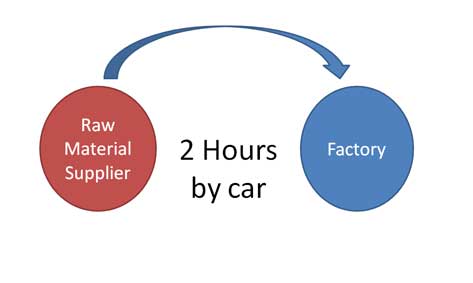

Most of our suppliers are just a 2-hour drive from our factory, meaning raw materials are always within reach.

FACTORY

Located in Huadu district, Guangzhou, the Opsmen factory is only 30 minutes by car from the head office. This high level manufacturing facility and warehouse procures materials, assembles, inspects, and delivers. Detailed discussions with the development team from the very initial designing stage, on through mass production, are key to delivering top-notch products to our customers.

Stay tuned: we’re also planning to build a “smart” factory over the next few years

You’re always welcome to join us for an online factory tour—please feel free to book one through our contact form.

| Factory Name |

Opsmen Tech Co., Ltd. Huadu Branch |

|---|---|

| Location |

6th Floor, Building No.1, No.7 Pingshan Private Industrial Park, Huashan Town, Huadu District, Guangzhou, Guangdong Province, China |

| TEL |

86 20 81179170 |

| FAX |

86 20 81179171 |

| Beginning of Operation |

Feb, 2017 |

| Site Area |

5000㎡ |

| Manufacturing Plant |

PCBA Inspection, Assembling, Testing, Packing, Warehouse Plant |

| Production Capacity |

About 1 million pcs per year |

|---|---|

| ISO |

ISO9001:2015 |

| Other Certification, Registration |

Medical Device Manufacturing Registration Certificate |

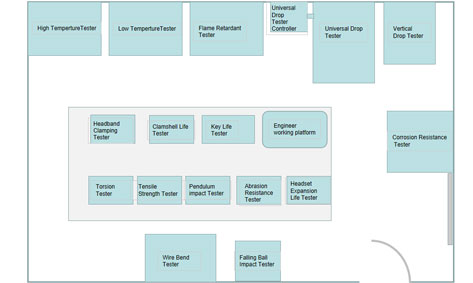

| List of Equipment Owned by us |

PCBA Tester |

5 Strengths for

Opsmen Factory

Opsmen not only offers customized development and manufacturing contract (ODM, OEM) services for our customers, but also precise OMS (Opsmen Manufacturing Services) – drawing on the resources and know-how of our very own factory.

1 Highly Collaborative Supplier Of Raw Material

2 hours by car

2-3 days delivery

2 Cost Control

Professional Purchasing Team

The delivery time from suppliers to the Opsmen factory is just 2-3 days, ensuring a stable lead time.

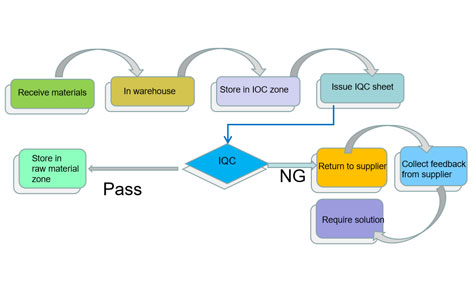

100% IQC

All inbound raw materials are carefully checked in order to reduce waste and secure quality.

High Efficient Skilled Workers

Skilled workers are the basis for the consistently top grade goods we handle and produce. Their know-how is also what guarantees a high production capacity, and the ability to bump it up on demand.

3 Production Process

Professional SOP

PCBA Electric Welding

Our superb PCBA provides a high degree of mechanical equipment integration, and that guarantees the soundness of finished electronic device components.

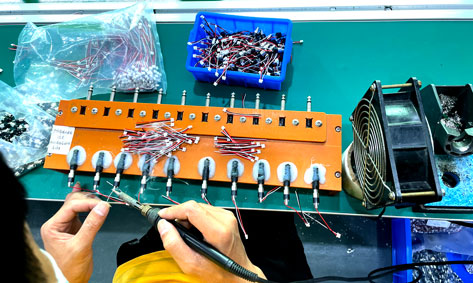

Wire Soldering

Our core skilled trades workers take exacting care in making sure every part is properly secured, connected, insulated, routed and set up.

Assembling

The average age of our assembling team staff is 23 years old – young enough to maximize the work output, old enough to be properly experienced, knowledgeable and integrated into the rhythms of the job